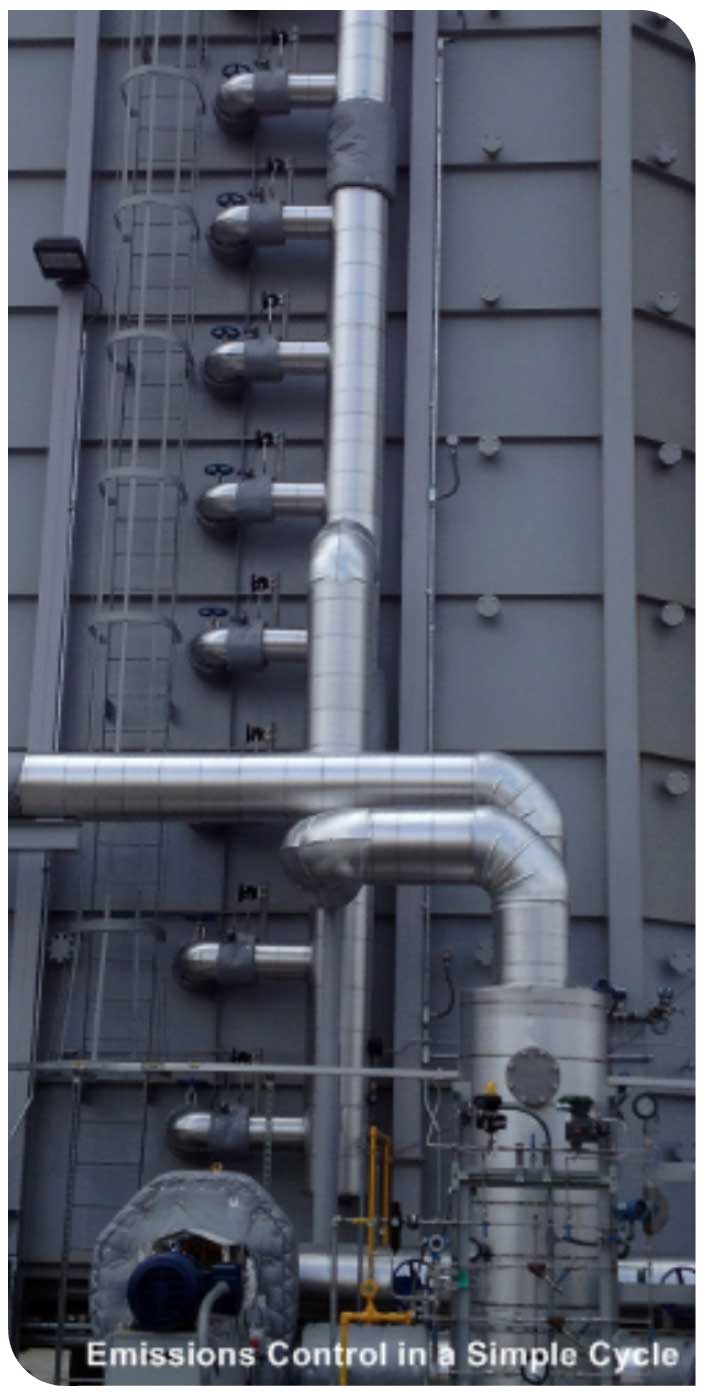

simple cycle

Full Production Scale Plant & Distributed Generation Facility Performance Testing

Plant & Facility (Contractual Acceptance or Routine)

Distributed Power • LNG Facilities • Gas Compression Stations • Pumping Stations

LPG Production • Oil Field Power Generation • Pipeline

Additional Tests

- Production Capacity

- Fuel Gas Consumption

- Ship Loading Capability

- LPG Recovery Rate

- First Year Operating Statistics and Performance Reporting

- Production Efficiency

- Overall Effectiveness

- Reliability

- Availability

- Utilization

- Pipeline Minimum FLow & Maximum Lead FLow

- Pipeline Delivery Pressure, Temperature, and Flow

- Power Output

- Heat Rate

- Noise Tests

- Capability Tests

- Auxiliary System Load

- On-Site Chromatograph Fuel Analysis

Component Testing

- Fired Equipment

- Frame Gas Turbine

- Aero Derivative Gas Turbine

- Industrial Gas Turbines

- Reciprocating Engines

- Combined Conversion Equipment

- Heat Recovery Steam Generator (HRSG)

- Steam Turbine

- Duct Burner

Production & Conveyance Equipment

- Liquefaction System

- Cryogenic System HD/MD/LD compressors and Pumps

- Fuel Gas Compressors

- Cryogenic Pumps

Auxiliary Equipment

- Condenser

- Cooling Tower

- Air Cooled Condenser

- Circulation Pump

- Feed water Pump

- Inlet Conditioning (Chiller, Fogger, Evaporative Cooler, Heater)

McHale Performance provides performance testing for the contract procurement of natural gas based plants and components; LNG and LPG production processes and facilities. Specifically, our performance testing is designed to verify contractual guarantees at the level of confidence expected by the parties of the contractual acceptance test and to ensure successful closure of the project.

McHale Performance also provides benchmark status performance testing to our clients to ensure that plant performance has not degraded to unacceptable levels and to identify where program improvements can be made to improve the efficiency, output, and economic performance. McHale can provide the required performance testing in order to verify the performance of individual units and multiple facilities to establish confident benchmarks for planning optimized coordinated plant operation and outage maintenance projects.

Technical Advisor

McHale Performance has technical advisors that are experienced in serving as “owner’s engineers” that identify, quantify, and mitigate risks associated with plant performance for our clients. We have assisted project owners, financial institutions, and legal counsel with advising/consulting services and performance audits. McHale Advisors understand the importance of reviewing proposed designs, development of strong contractual language, construction monitoring, and witnessing of key tests to ensure performance guarantees are achieved with confidence so to ensure the success of a project.

Test Code Specialists

McHale Performance is recognized throughout the power generation market as a specialized engineering group that provides superior testing and plant performance improvement services. McHale is actively involved and versed in the ASME Test codes and has extensive experience conducting tests utilizing international test codes and standards:

- ASME PTC 46 – Overall Plant Performance

- ASME PTC 22 – Gas Turbines

- ISO 2314 – Gas Turbines – Acceptance Tests

- DIN 4341 – Gas Turbines – Acceptance Tests

- BS 3135 – Specification for gas turbine acceptance test

- ASME PTC 51 – Gas Turbine Inlet Conditioning

- ASME PTC 6.2 – Steam Turbines in Combined Cycle

- DIN-1943 – Thermal acceptance tests of steam turbines

- BN EN 60953 – Rules for steam turbine thermal acceptance tests

- DIN 1942 – Acceptance Test Code for Steam Generators

- ASME PTC 4 – Fired Steam Generators

- ASME PTC 4.4 – Gas Turbine Heat Recovery Steam Generators

- ASME PTC 19.1 – Test Uncertainty

- ASME PTC 19.22 – Data Acquisition Systems

- ASME PTC 19.5 – Flow Measurement

- ASME PTC 12.2 Steam Surface Condenser

- ASME PTC 36 Measurement of Industrial Sound

- CTI ATC-105 – Acceptance Test Code for Water Cooling Towers

- CTI ATC-140 – Isokinetic Drift Test Code

- ASME PTC 8.2 Centrifugal Pumps

- ASME PTC 9 Displacement Compressors, Vacuum Pumps and Blower

- ASME PTC 10 Compressors and Exhausters

- CTI ATC-150 – Acceptance Test Procedure for Wet Dry Plume Abatement Cooling Towers

We are experienced on how to properly apply these codes and other international standards to successfully demonstrate contractual acceptance with the level confidence for lenders, owners, OEM’s and EPC’s demand.

Qualified & Impartial Test Personnel

McHale has worked with a variety of EPC contractors, plant owners, and manufacturers throughout the power industry. The McHale team is known for quick response time, expertise in plant and component issues, and accurate results.

Code Compliant & Calibrated Test Equipment

McHale has a complement of test equipment designed to augment the standard built-in natural gas power plant or facility instrumentation so as to improve the uncertainty of performance testing necessary to meet the desired confidence for contractual acceptance and for provision of information for long term financial projections of the assets.

- Remote Data Acquisition for Long Period Testing and Analysis

- Pressure and Differential Pressure Transmitters

- Ambient Temperature, Humidity, and Wind Sensors

- Three Phase Revenue Quality Power Meters

- Three Phase Power Quality Monitors

- Exhaust Gas, Steam, and High Temperature

- Clamp on Ultrasonic Flow Meters

- Clamp on Temperature Sensors

- Infrared Temperature Imaging

- Mobile Data Loggers

- Type S, 3 Hole and 5 hole probe Pitot Tubes

Natural Gas Measurement Solutions

McHale has a complement of metrology services to support the collection and analysis of Natural Gas Fuels

- On Site Natural Gas Chromatography Analysis

- Laboratory Natural Gas Chromatography Analysis

- Composition of Natural Gas by Gas Chromatography – ASTM D 1945

- Calorific Value and Specific Gravity of Gaseous Fuels – ASTM D 3588

- Specific Gravity at 60oF and 1 atmosphere – ASTM D 3588

- Molecular Weight & Density – Calculated

- Centerline Gas Sampling Probes

- Natural Gas Spot Sample Collection Bottles