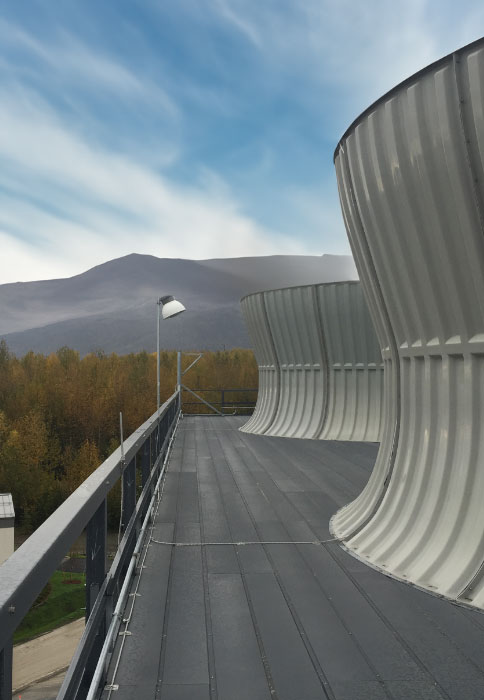

CTI Cooling Tower

As a corporate member and licensed holder of the Cooling Technology Institute (CTI), McHale & Associates specializes in cooling tower testing and consultation. We conduct acceptance and routine tests on cooling towers and related equipment, ensuring optimal performance. Our licenses cover both thermal performance testing and drift emission testing, providing comprehensive services to meet all cooling tower testing requirements.

Why Choose McHale?

We are a full-service provider for all CTI Testing Services.

Our team is highly-experienced, responsive, and flexible.

We specialize in solving complex process issues and delivering effective solutions

… even in challenging testing conditions.

We provide fair and transparent pricing with no hidden costs.

Licensed Cooling Tower Services

CTI ATC-105 Thermal Testing

Cooling towers play a crucial role in removing excess heat from a plant’s processes. By lowering the cooling tower outlet temperature, the plant’s thermal performance can improve, leading to increased efficiency and revenue. One of the best ways to optimize cooling tower performance is through a CTI ATC-105 Thermal Performance Test.

With over 30 years of experience, McHale & Associates specializes in thermal performance testing using highly accurate, CTI-compliant equipment. Whether you’re looking for CTI ATC-105 compliance testing for contractual requirements or seeking a detailed performance assessment, we offer tailored testing solutions to meet your specific needs and improve your cooling tower’s efficiency.

CTI ATC-140 Drift Testing

Drift emissions from cooling towers are an often-overlooked source of air pollution, and with growing concerns about health and environmental impact, plants are increasingly focused on drift reduction and drift testing.

Cooling tower drift occurs when small droplets of circulating water are discharged into the air as particulate matter (PM). These particulates can contain harmful chemicals and bacteria, such as Legionella, which pose risks to respiratory health. In addition, drift can lead to water loss, corrosion of nearby equipment, and environmental damage over time.

At McHale & Associates, our highly trained CTI Drift Leads utilize a CTI-compliant Drift Test Kit to deliver precise and reliable results. Whether the test is for contractual obligations, a water loss reduction initiative, environmental air permitting, or LEED drift eliminator certification, we provide accurate testing services to ensure compliance and improve operational efficiency.

CTI STD-201 Thermal Certification Testing

CTI STD-201 is a certification program by the Cooling Tower Institute (CTI) that verifies whether all models within a line of packaged cooling towers meet the published thermal performance ratings. To maintain CTI certification, manufacturers must undergo an initial Certification Test and complete re-certification testing annually.

The CTI STD-201 certification process can be challenging for manufacturers, making it crucial to partner with a reliable and experienced testing company. McHale & Associates specializes in STD-201 certification testing, guiding manufacturers through the entire process, from the initial certification to maintaining a fully CTI Certified line of cooling towers.

CTI ATC-128 Sound Testing

Cooling towers can be a major source of noise pollution, affecting both the surrounding community and potentially causing hearing loss for employees. To address this, McHale & Associates offers a specialized noise testing approach, utilizing CTI ATC-128 and other relevant noise standards. Our targeted testing helps identify the root causes of excessive noise and enables the development of effective physical, administrative, and engineering barriers to reduce the cooling tower’s noise footprint.

cooling tower performance test procedure

Qualified & Impartial Test Personnel

At McHale & Associates, we uphold the highest standards for Lead Thermal Testers, as required by our CTI license. Our commitment goes beyond CTI standards, ensuring our team meets rigorous internal requirements for exceptional quality. This enables us to provide the most reliable thermal testing services and unmatched schedule flexibility to meet your needs.

Code Compliant & Calibrated Test Equipment

McHale’s state-of-the-art ISO 17025 accredited calibration laboratory in Knoxville, Tennessee offers advanced calibration and testing services. Our lab is equipped with cutting-edge test equipment to enhance testing accuracy, reduce uncertainty, and ensure compliance with code requirements. Whether for contractual acceptance or routine status testing, we provide precise, reliable results that exceed industry standards.

|

|

CLICK HERE FOR MORE INFORMATION ON TEST EQUIPMENT

Characterization of Elliptical Pitot Tube for Water Flow Measurements

In 2018, CTI switched from simplex pitot tubes to an elliptical style pitot tubes for water flow measurements. This change was made to reduce the impact of change in Reynolds number on the calibration coefficient of the pitot tube.

In addition, the new design incorporated a one-inch (1”) round body to reduce the vibration of the pitot. In this process, the blockage area of the pitot probe was increased.

More Info